All Posts

December 15, 2022

Students Visit Site for Caster Digital Twin Project

CIVS Graduate students Aleeha Zafar and Xibin Zhou, Senior Design students Qingyun Pu and Shiyu Wang, and CIVS mentor Kyle Toth, Senior Research Engineer, had the opportunity to spend a day touring Caster #1 at Burns Harbor, Cleveland-Cliffs’ second-largest U.S. facility, as part of their 3-D modeling work for the Continuous Caster Digital Twin project.

February 2, 2023

NSF RET Summer Program Returns for STEM Teachers

After a highly successful Research Experience for Teachers (RET) Program in 2021 & 2022, CIVS will again open its doors to High School and Community College teachers in the summer of 2023. The RET Program, sponsored by National Science Foundation through a three-year grant, will take place from June 12th – July 21st, 2023

March 16, 2023

ArcelorMittal Global Representatives Tour CIVS

ArcelorMittal representatives visited CIVS on March 2nd, 2023. The goal of the visit was to discuss CIVS capabilities and ongoing/future collaborations with ArcelorMittal.

February 16, 2023

Gerdau Technical Manager and Staff Discuss Collaborations at CIVS

Representatives from Gerdau visited the CIVS research center. CIVS projects and technologies were demonstrated.

March 13, 2023

Prototype Sensor for Casting Rate Tested at #7 Blast Furnace at Cleveland-Cliffs

On March 1st, 2023, Purdue Northwest and Purdue University-West Lafayette research team members visited the Cleveland-Cliffs plant in Indiana Harbor to discuss the results of simulation efforts and test an upgraded prototype for the Integrated Virtual Blast Furnace casting-rate imaging sensor. This visit supported efforts on the Integrated Virtual Blast Furnace project as well as a parallel research project for investigating high-rate natural gas injection at Cleveland-Cliffs facilities.

February 3, 2023

Virtual Die Casting Simulator Disseminated to NADCA Members

CIVS Researcher John "Jack" Moreland presented the final report for the Virtual Die Casting Simulator on February 2, 2023, at the NADCA Research & Development Committee meeting held at the University of California, Irvine. The presentation was a hybrid (in-person and virtual) and included attendees from the die-casting industry, academia, and government organizations.

March 15, 2023

CIVS Director Presents at National Academies Smart Manufacturing Workshop

Dr. Chenn Zhou was invited to be a panelist at the Workshop on the Broader Impacts of Smart Manufacturing on March 7th in Washington DC, organized by the National Academies of Science, Engineering, and Medicine. During the workshop, Dr. Zhou made a 15-minute presentation on “Impacts of Smart Manufacturing on Sustainability”, which highlighted her journey in Smart Manufacturing since 1995, as well as project examples and their impacts on energy efficiency, decarbonization, process operation and maintenance, and workforce development in steel and other industries.

December 14, 2022

CIVS Helps Steel Industry Tackle Decarbonization Issues

PNW’s Center for Innovation through Visualization and Simulation (CIVS) is at the forefront for researching two of the most important topics in manufacturing: digitalization and decarbonization. Read The Times of Northwest Indiana’s coverage of recent CIVS projects and how researchers use cutting-edge tools for innovation with industry partners.

December 16, 2022

Student Success Story: Yanan Song

Congratulations to Yanan Song who recently graduated with his Master of Electrical and Computer Engineering after defending his thesis titled “Feature Fusion Deep Learning Method for Video and Audio Emotion Recognition.”

March 16, 2023

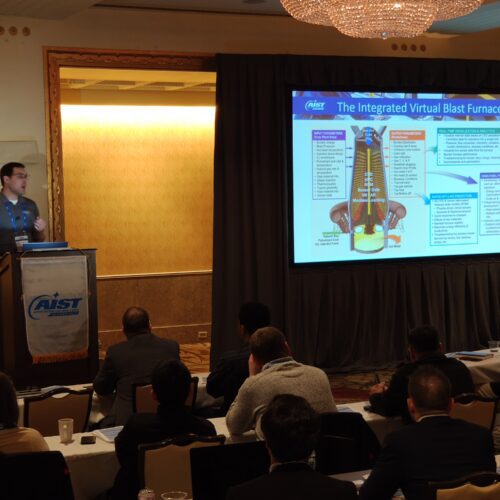

New Efficient Blast Furnace Model Presented at Digital Transformation Forum

Our research on “A Multi-Input & Output Model for Blast Furnace Operational Guidance Using a Pre-generated CFD Simulation Dataset” was presented by Professor Tyamo Okosun at the 2023 AIST Digital Transformation Forum for the Steel Industry on March 8th, in Pittsburgh, Pennsylvania. This research uses machine learning and a database of CFD modeling results to develop a Reduced-Order Model (ROM) for operators and engineers to quickly perform "what-if" calculations on their blast furnaces, which provides a useful tool for physics-based and data-driven quick decision making. This is a part of a large collaborative project to develop an Integrated Virtual Blast Furnace sponsored by the Department of Energy.