CIVS Hydrogen Research Published in JOM

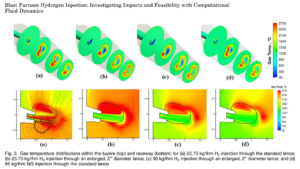

Side view (top) and top view (bottom) of temperature distributions in the raceway region for the baseline scenario

JOM, The Journal of The Minerals, Metals & Materials Society (TMS), published a CIVS research paper entitled “Blast Furnace Hydrogen Injection: Investigating Impacts and Feasibility with Computational Fluid Dynamics” authored by CIVS Research Associate Professor Tyamo Okosun in collaboration with CIVS graduate student, Samuel Nielson, and CIVS Director, Prof. Chenn Zhou. The ongoing Blast Furnace research conducted on energy efficiency and de-carbonization by CIVS staff and students is supported by the members of the Steel Manufacturing Simulation and Visualization Consortium (SMSVC) and the Integrated Virtual Blast Furnace project funded by the U.S. Department of Energy’s Advanced Manufacturing Office.

The article, based on the research of Professor Okosun and graduate student Sam Nielson, explains how the stability of blast furnace operation is directly impacted by low-carbon fuel injection and the limitations which arise due to the quenching effects of Hydrogen reactions with coke and iron ore. Computational fluid dynamics was employed to study how standard natural gas injection could be replaced or combined with hydrogen injection. It was reported that stable operation could be achieved at significant hydrogen injection rates, both in isolation and in combination with natural gas. Carbon emissions were reduced by more than 5% in some cases, presenting possible approaches for emissions reduction. The work also confirmed the significant quenching effects of hydrogen injection on furnace flame temperatures, creating instability if injection rates are too high.