CIVS Lands $7 Million DOE IEDO grant for Electric Arc Furnace

The U.S. Department of Energy (DOE) Industrial Efficiency and Decarbonization Office (IEDO) recently awarded PNW CIVS a grant with $7,158,034 for the decarbonization of Electric Arc furnace (EAF). The project is entitled “Technical Development and Industrial Demonstration of Net-Zero Carbon EAF Steelmaking with Alternative Injection and Stirring Technologies”. The principal investigator of the project is Dr. Tyamo Okosun (CIVS Associate Director for Research). The co-principal investigators are Dr. Armin Silaen (CIVS Associate Director for Operations) and Dr. Chenn Zhou (CIVS Director). Other key project participants include Drs. Chris Pistorius and Valerie Karplus from Carnegie Mellon University, Joe Maiolo from Linde, and Dr. Eugene Pretorius from Nucor.

The U.S. Department of Energy (DOE) Industrial Efficiency and Decarbonization Office (IEDO) recently awarded PNW CIVS a grant with $7,158,034 for the decarbonization of Electric Arc furnace (EAF). The project is entitled “Technical Development and Industrial Demonstration of Net-Zero Carbon EAF Steelmaking with Alternative Injection and Stirring Technologies”. The principal investigator of the project is Dr. Tyamo Okosun (CIVS Associate Director for Research). The co-principal investigators are Dr. Armin Silaen (CIVS Associate Director for Operations) and Dr. Chenn Zhou (CIVS Director). Other key project participants include Drs. Chris Pistorius and Valerie Karplus from Carnegie Mellon University, Joe Maiolo from Linde, and Dr. Eugene Pretorius from Nucor.

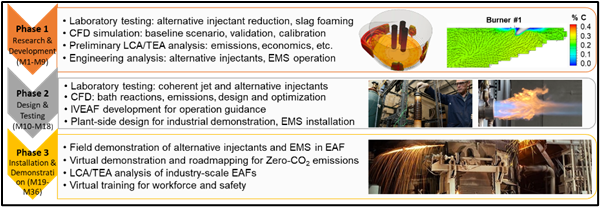

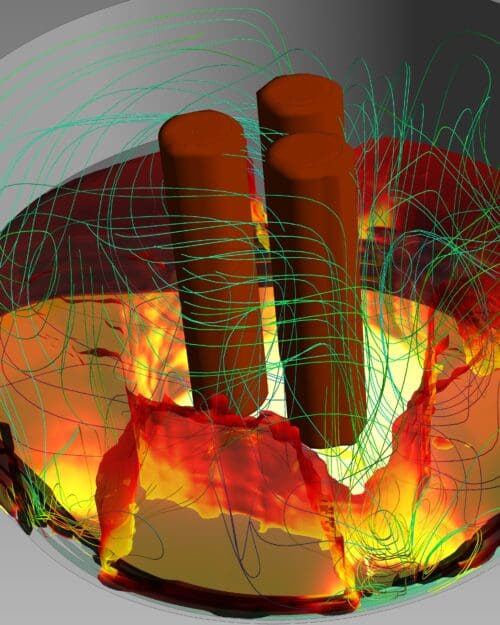

This project will leverage expertise from industry and academia in a nationwide collaboration to pioneer an industrial-scale demonstration of alternative refining injection technology and electromagnetic stirring (EMS) in the Electric Arc Furnace (EAF) process. Through industrial trials, PNW CIVS and its partners aim to demonstrate a range of alternative stirring, oxidation, and foaming technologies in a commercial scale EAF. The team will develop novel gas injection technologies aimed at delivering low carbon reducing gases deep into the steel bath, utilize ‘soft’ oxidation technologies (such as CO2 to enable efficient mixing), develop alternative foaming agents, and ultimately culminate in a first-of-a-kind demonstration of EAF steelmaking using no fossil-carbon injectants supplemented by electromagnetic stirring technology. EAF steelmaking is dominant in the U.S. and the elimination of fossil carbon injection in its processing will reduce direct emissions by 40%. The project includes the development of an integrated virtual electric arc furnace (IVEAF) platform to give steelmakers the tools to optimize their own processes and achieve widespread emissions reductions.

The team will integrate various efforts and technologies to develop and implement a demonstration of alternate injectants with EMS in an industry EAF. An integrated approach employing high-fidelity computational modeling, LCA & TEA, advanced visualization, detailed lab experimentation, industrial field demonstration will be used to 1) provide knowledge and guidance for replacing fossil-carbon injection and optimizing oxidation in industrial EAFs for CO2 reduction, and to 2) develop a multifunctional Integrated Virtual Electric Arc Furnace (IVEAF) platform as a guidance and analysis tool for developing strategies and evaluating impacts of different operating conditions on alternative injection EAF operation, and 3) benefit underserved communities through workforce development, virtual training, and reduced fossil fuel use.

EAF steelmaking is dominant in the U.S. Fossil-carbon injection is a common element of EAF steelmaking for slag foaming and FeO recovery. A successful industrial demonstration replacing particulates with controlled oxidation, gaseous reductant injection, and alternative slag foaming, supported by EMS, is key to establishing that these technologies can be combined to reduce CO2 emissions without negatively impacting productivity and product quality.