CIVS Director Presented EAF CFD Modeling at Electric Steelmaking Conference and Visited Linde Lab in Germany

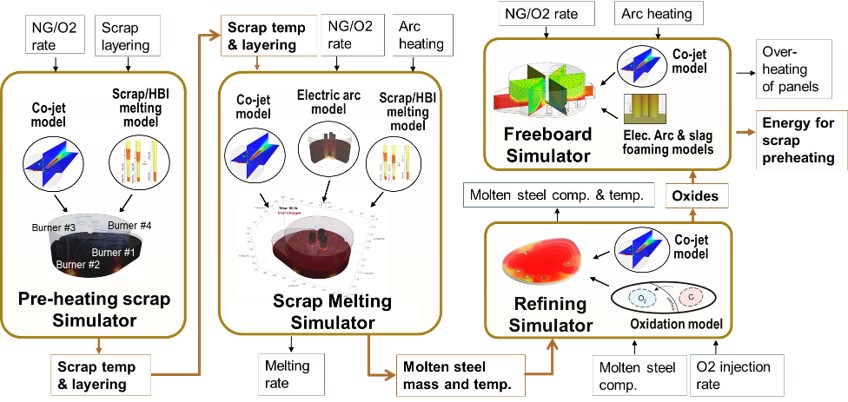

The 13th European Electric Steelmaking Conference 2024 was held in Essen, Germany on June 3-7. CIVS Director, Dr. Chenn Zhou presented “CFD Modeling of Electric Arc Furnace for Process Optimization”. Other co-authors of the paper included CIVS graduate student Shiyu Wang, CIVS Research Scientist Dr. Orlando Ugarte, and CIVS Associate Director for Research Dr. Tyamo Okosun. Dr. Zhou described our state-of-the-art EAF model by integrating phenomenological models and various simulators, which has been used to simulate stage-by-stage EAF operations and used for troubleshooting and optimization. It will also be used for developing decarbonization technologies. Dr. Zhou’s talk generated excitement and lively discussions.

The 13th European Electric Steelmaking Conference 2024 was held in Essen, Germany on June 3-7. CIVS Director, Dr. Chenn Zhou presented “CFD Modeling of Electric Arc Furnace for Process Optimization”. Other co-authors of the paper included CIVS graduate student Shiyu Wang, CIVS Research Scientist Dr. Orlando Ugarte, and CIVS Associate Director for Research Dr. Tyamo Okosun. Dr. Zhou described our state-of-the-art EAF model by integrating phenomenological models and various simulators, which has been used to simulate stage-by-stage EAF operations and used for troubleshooting and optimization. It will also be used for developing decarbonization technologies. Dr. Zhou’s talk generated excitement and lively discussions.

Over 350 participants from all over the world came together at the Philharmonie Essen in Germany to discuss the latest technologies and developments in the field of electric steelmaking; one of the largest in conference history. The conference provided an extensive program with over 90 presentations on topics such as electric arc furnace technologies, DRI/HBI melting, energy efficiency and strategies for environmentally friendly steelmaking. In addition to the technical dialogue, the evening event and the plant visits offered many opportunities to network. The accompanying trade exhibition also presented the latest products and services relating to electric steelmaking and provided plenty of opportunities for discussions and networking. The 13th European Electric Steelmaking Conference 2024 demonstrated that the electric steel route is a central building block for the transformation to a climate-neutral steel industry. The conference is organized by the Steel Institute VDEh.

The European steel industry has set a goal to achieve carbon neutrality by 2050. Steel companies are actively developing “smart and efficient factories” and to solve skills shortages.

During the trip, she also visited Linde’s very impressive combustion lab in Munich. The combustion lab facility will be used to test flameless H2 burner performance in our DOE $10M reheating furnace project.