CIVS EAF Research Work Published in Two Top Journals

Two top journals, Applied Thermal Engineering (ATE) and Metallurgical and Materials Transactions B (MMTB), published two research papers entitled “Effect of the coherent jet burner on scrap melting in electric arc furnace” and “Simulation of Scrap Melting Process in an AC Electric Arc Furnace: CFD Model Development and Experimental Validation” authored by Yuchao Chen. Yuchao is a research assistant in CIVS who recently received his doctorate in Mechanical Engineering with a concentration in fluid mechanics and heat transfer from Purdue University West Lafayette.

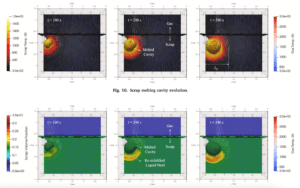

The research paper published in ATE established an innovative comprehensive CFD model including a scrap melting model and a coherent jet model based on the detailed physical principles, which couples the solid–liquid-gas three-phase system with coherent jet and scrap melting/re-solidification for the investigations of key evaluation factors including burner efficiency, scrap heating rate, and scrap melting cavity. An experiment was designed and implemented specifically in an industrial-scale EAF for validating the proposed model. The model was employed to explore the impacts of burner power, scrap porosity, scrap preheat temperature and scrap blockage on burner energy utilization. An understanding and guidance of coherent jet burner operations were provided based on the studies for more effective scrap melting.

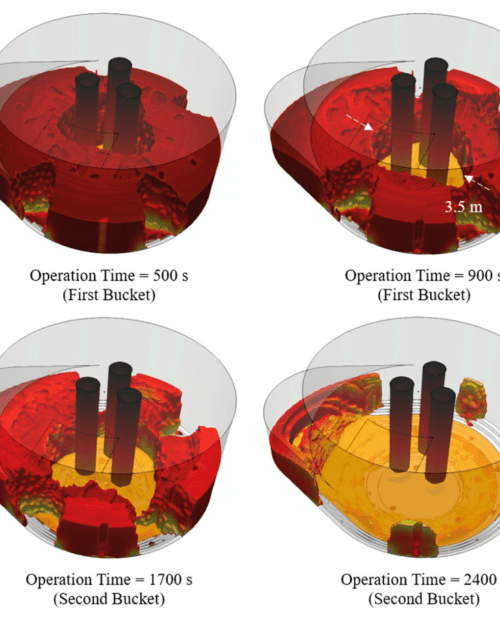

The research paper published in MMTB further developed and integrated the electric arc model into the above comprehensive CFD model to capture the arc melting in the industry-scale EAF. The CFD-compatible Monte Carlo method and electrode regulation strategy were developed respectively to predict the arc radiative heat dissipation and track the instant electrode movement. The experiments for the scrap melting by both electric arc and coherent jet burner were designed and implemented in the industry-scale NLMK 150-ton EAF for the model validation. The proposed comprehensive CFD model was applied to simulate the scrap melting process under the NLMK EAF typical run, and the scrap melting behavior, the electric arc performance, and the burner performance were evaluated and discussed based on the simulation results.