PNW CIVS Collaborating with ArcelorMittal and Oak Ridge National Lab on DOE HPC4Mfg Supercomputing Grant

…

“Reduced Order Modeling and Performance Prediction for Steel Refining Ladle Processing via High Performance Computing.”

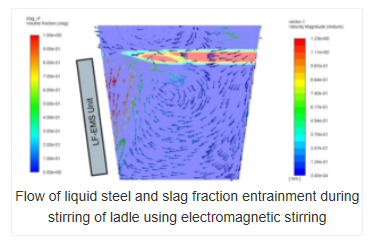

ArcelorMittal is collaborating with Oak Ridge National Laboratory (ORNL) and Purdue University Northwest to reduce the yield loss caused by impurities forming in the refining ladle process. In the steelmaking process, impurities must be eliminated to achieve optimal product performance. The only way to remove impurities is when the steel is molten. This study, taking place at the ladle at Indiana Harbor’s #3 steel producing operation, will examine techniques to produce cleaner steels for our customers. The goal is to conserve energy for ArcelorMittal USA by increasing the probability of melting steel correctly the first time.

“We have a long history working with Purdue University Northwest and they have vast expertise in the ladle process as well as simulating that process,” said Pallava Kaushik, manager, steelmaking and casting, ArcelorMittal Global Research and Development, East Chicago. “This is perfect collaboration with ArcelorMittal representing the operations, Purdue Northwest representing academia and ORNL providing computer devices. We are expecting usable results which can be effectively implemented during the ladle refining process in multiple plants in our company.”

HPC will allow faster calculations to evaluate multiple scenarios in a shorter time with the end goal of achieving process efficiency, which will reduce energy consumption at ArcelorMittal.

Read the full article here: